Removing or Sweetening of Mercaptan Compounds in Hydrocarbon Streams

MERICAT™ | Caustic Sweetening of Mercaptans

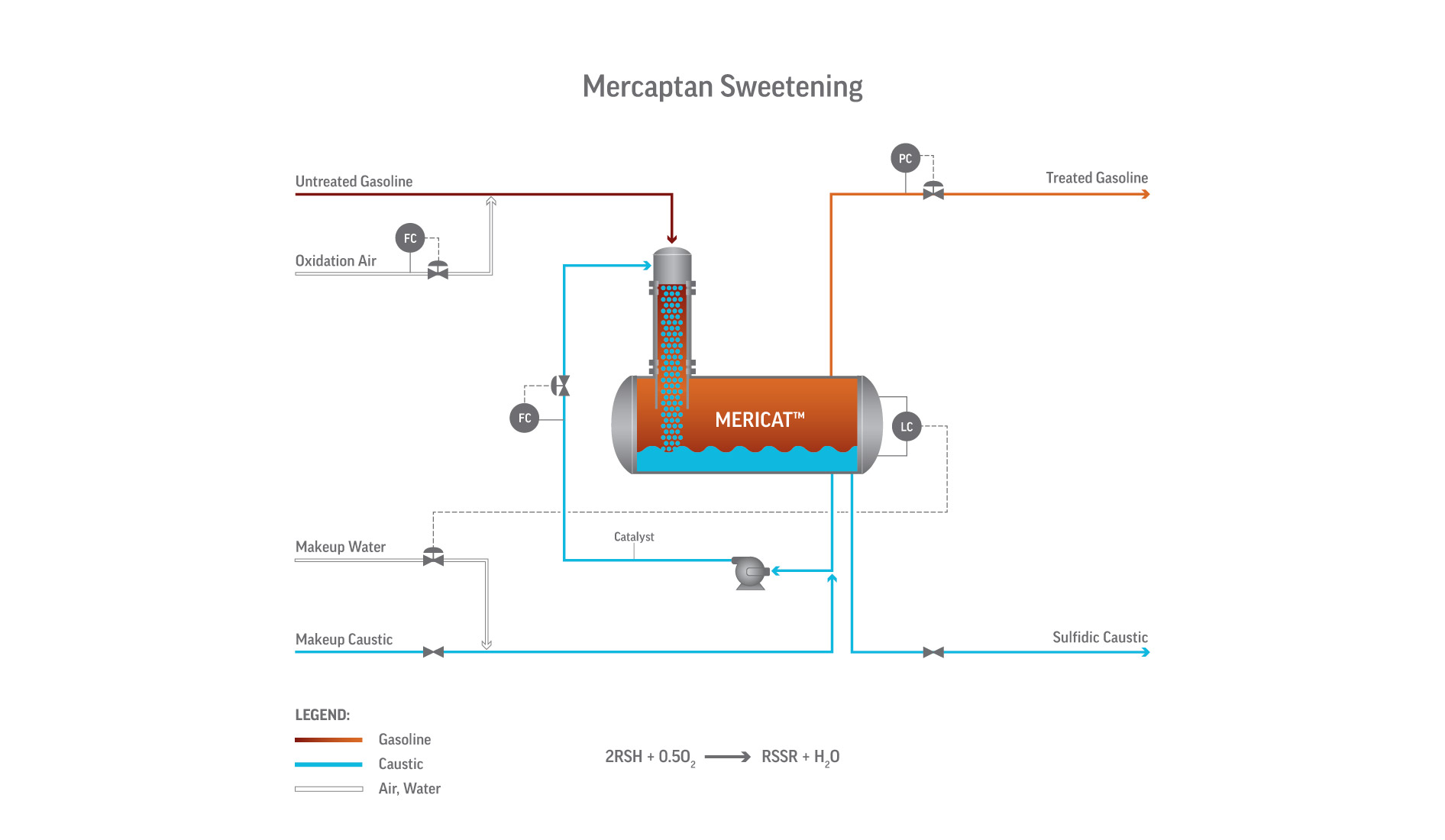

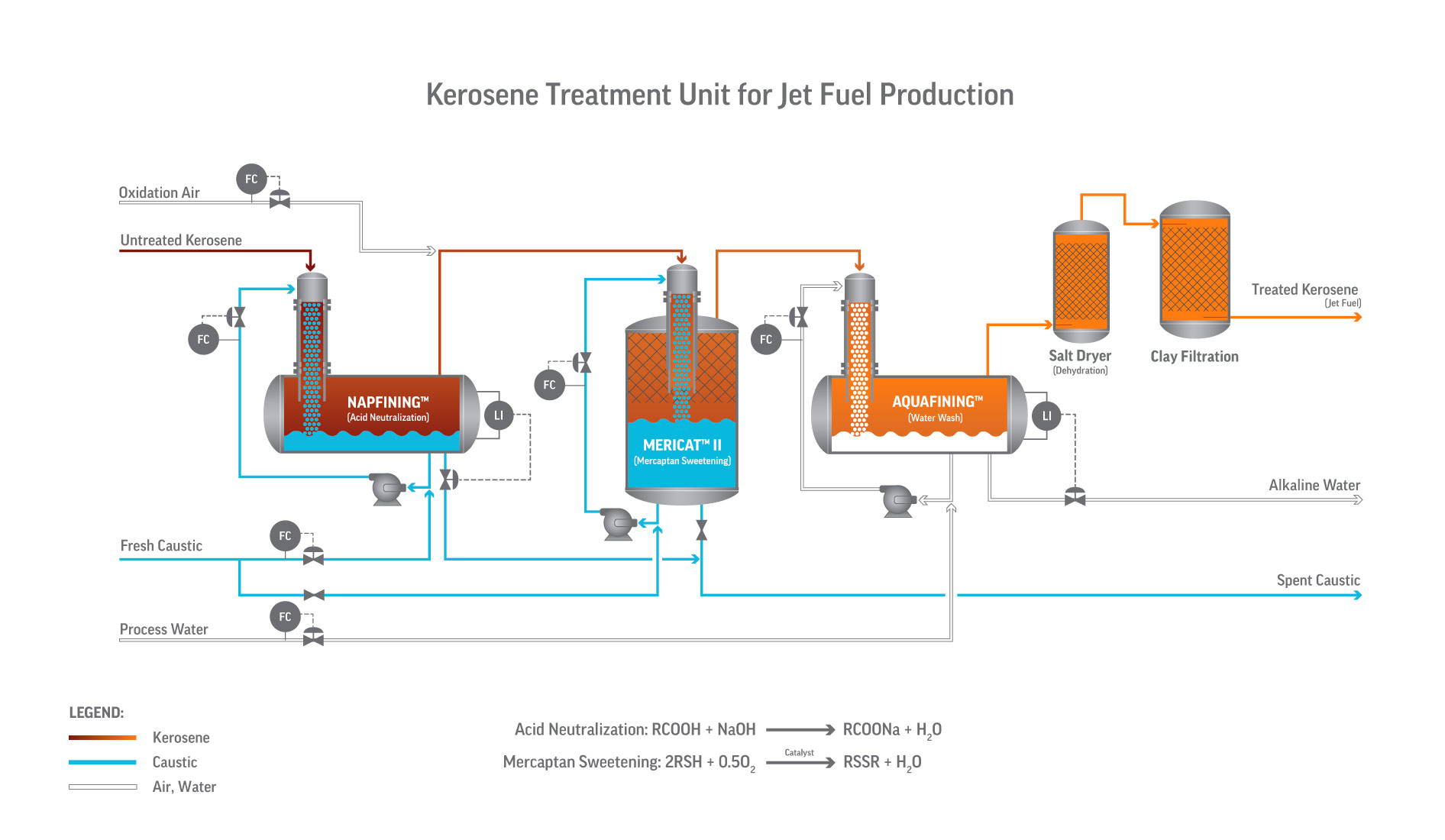

First licensed in 1977, MERICAT™ technology from Merichem Technologies has been successfully used in gasoline/naphtha, condensate and crude oil streams for the sweetening of mercaptan compounds. With our proprietary FIBER FILM® Contactor as the mass transfer device, MERICAT™ uses caustic/catalyst/air as treating reagents.

Advantages

- Reduces mercaptan content, using a strong caustic to meet mercaptan specifications and pass Doctor tests

- Allows customers to meet pipeline specification requirements for NGL, Y-grade fuels, pentane or condensate

- Simple and proven technology for sweetening light mercaptans in a hydrocarbon stream; a single vessel can achieve the RSH sweetening—no need for additional settling vessels

- Removes odorous RSH with minimal processing to meet total sulfur specifications

FFC Plus™ Technology

The latest iteration of Merichem Technologies’ FIBER FILM® Contactor technology, FFC Plus™ can increase hydrocarbon treating rates by up to 150 percent as compared to earlier designs.

Established Performance

For over half a century, Merichem Technologies has provided innovative solutions to the oil and gas industry, establishing a reputation of expertise in caustic treatment technology and service solutions. Equally uncommon is our dedication to our customers and solving their problems.

Support, A to Z

The depth of Merichem Technologies’ expertise is reinforced by the breadth of its capabilities, which include solution design, engineering, fabrication, research and development, testing and service.