Sweetening Mercaptans in Kerosene, Jet Fuel, Middle Distillate and Condensate

MERICAT™ II and MERICAT™ J | Caustic Sweetening of Mercaptans

MERICAT™ II and MERICAT™ J technologies are proven solutions for sweetening heavy mercaptans contained in kerosene, jet, middle-distillate and condensate.

When used with Merichem Technologies’ proprietary FIBER FILM® Contactor high-efficiency mass-transfer device, these technologies reduce the CAPEX and space requirements associated with conventional solutions.

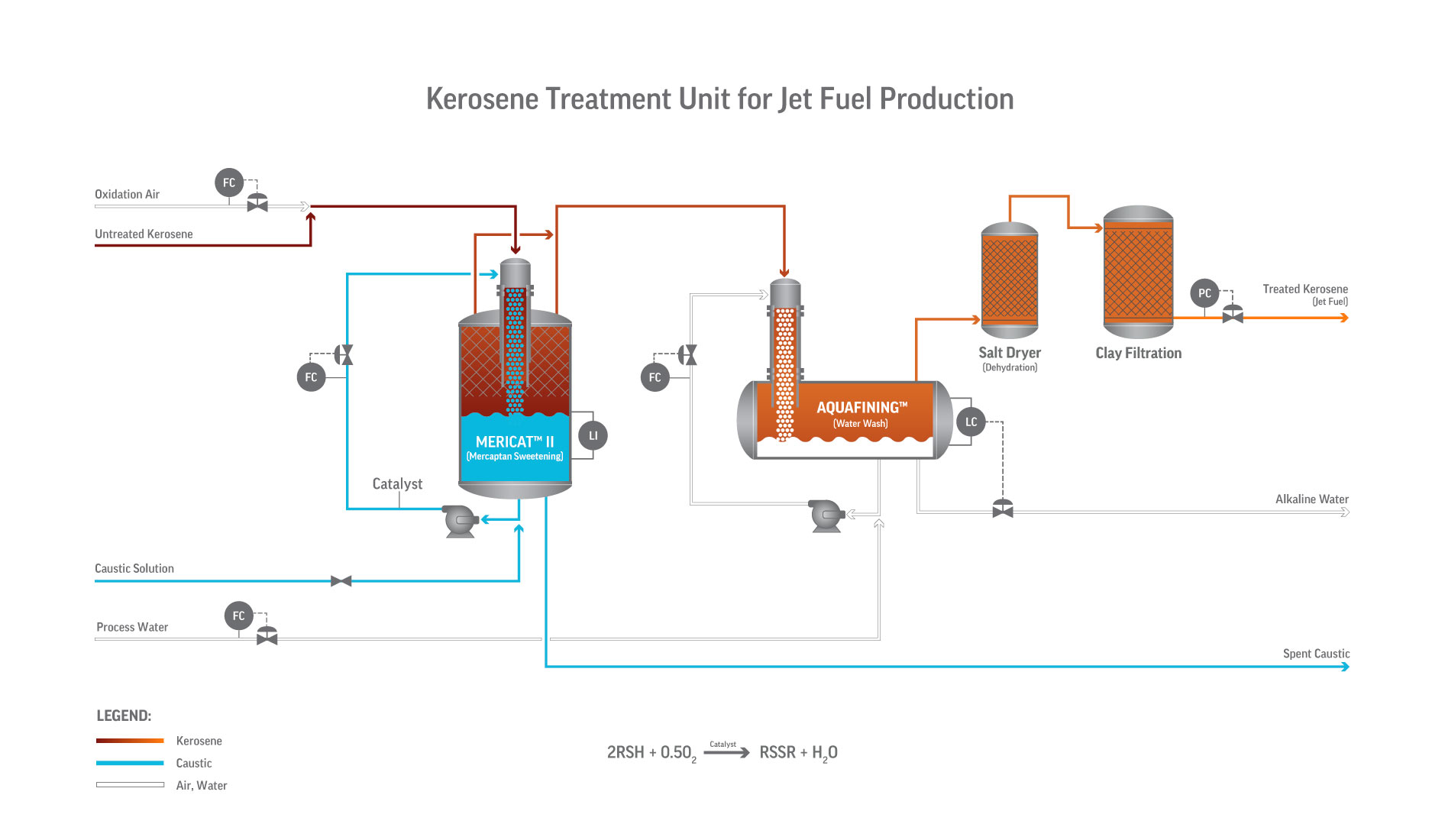

MERICAT™ II Advantages

Used with a carbon bed, this technology is typically applicable to the treatment of kerosene, jet fuel and middle-distillate streams.

- Reduces mercaptan content

- Uses caustic to meet mercaptan specifications and pass Doctor tests

- Often paired with NAPFINING™ for removal of naphthenic acids as well as AQUAFINING™ to scrub sodium and surfactants; uses salt and clay treatment for final polishing

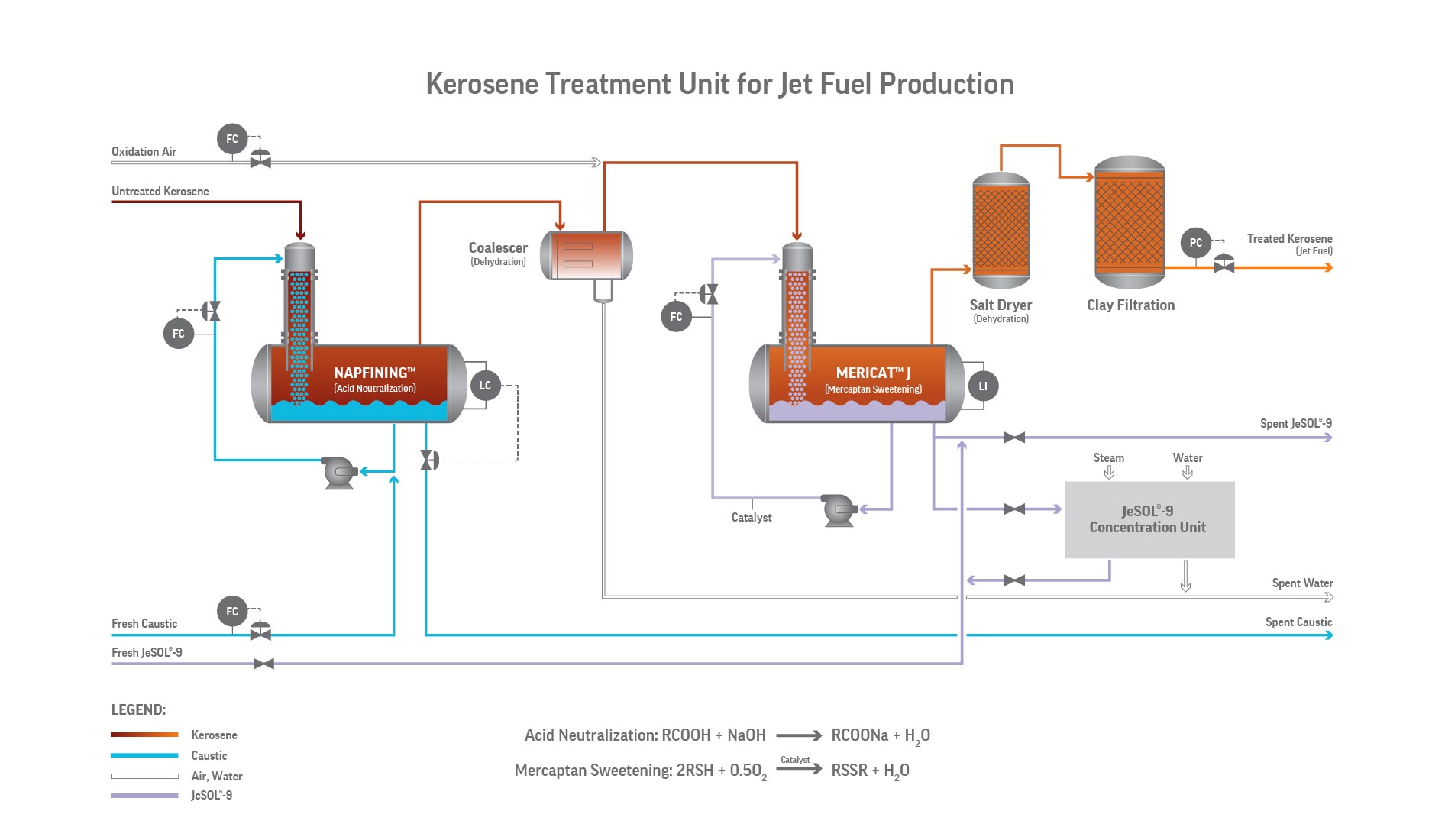

MERICAT™ J Advantages

Used without a carbon bed, this technology requires no carbon handling, purchase, cleaning, maintenance or disposal costs.

- No carbon fouling or deactivation resulting in off-spec product

- Extremely effective oxidation reactor for heavy or recombinant mercaptans

- Capable of removing naphthenic acids without affecting mercaptan oxidation performance

- Uses proprietary JeSOL®-9 solution, which provides full lifecycle responsibility by Merichem Technologies

- Eliminates effluent disposal by offering ongoing supply and return of JeSOL®-9 solution

- Used with FIBER FILM® Contactor

- Lower cost at high mercaptan levels or high throughput

- Reduced color body formation

- Can often be retrofitted into legacy carbon beds to increase capacity and treatability

FFC Plus™ Technology

Merichem Technologies’ most advanced FIBER FILM® Contactor technology to date is used on every MERICAT™ J installation.

Established Performance

Merichem Technologies has developed proven technologies to the oil and gas industry for over 50 years. We have built a global reputation for expertise in caustic treatment technology and service solutions, delivered with dedicated and responsive service to our customers.

Extensive Capabilities

We are a full-service solution provider. Whether it’s licensing technology, guidance, design, engineering, fabrication, testing or implementation, Merichem Technologies has the resources to fill in your blanks.