Innovative Process Solutions Powered by Expert Service

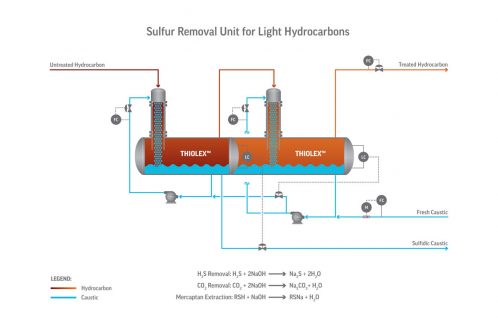

Remove RSH, H2S, and COS with THIOLEX™

Featuring our proprietary FIBER FILM® Contactor, Merichem Technologies’ THIOLEX™ technology uses a caustic solution to remove mercaptan compounds and other impurities. It allows for total sulfur reduction in hydrocarbon streams to meet client specifications while delivering greater design and operational flexibility, improving sales and profits.

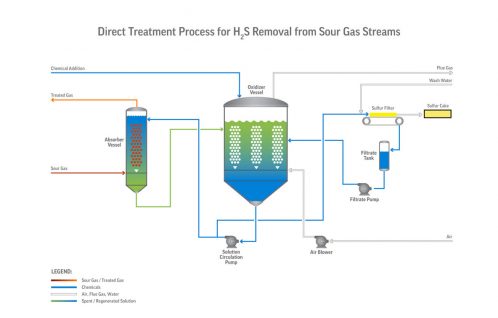

H2S Removal with LO-CAT®

Merichem Technologies’ patented liquid redox system uses a chelated iron solution to convert dangerous H2S into innocuous, elemental sulfur. Chemical-based, it offers greater reliability and flexibility than biological treatment—with no liquid waste streams.

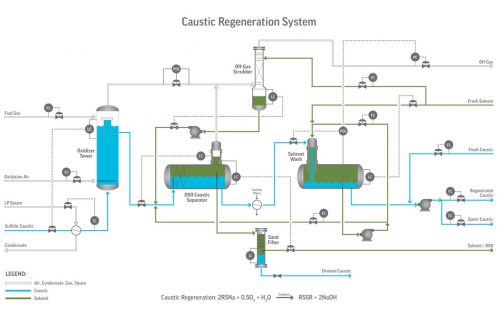

Regenerate Spent Caustic Product with REGEN®

Merichem Technologies’ REGEN® technology reduces caustic consumption through the regeneration of the caustic solution. With applications in all caustic streams used in mercaptan treating processes, it allows mercaptides to be oxidized into disulfide oil (DSO), recovering sodium hydroxide and minimizing virgin caustic consumption.

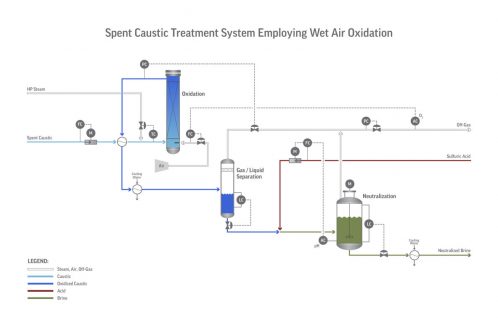

Treat Your Spent Caustic On‑Site with MERICON™

MERICON™ I, II, III and neutralization treatment technologies are used in the processing of spent caustic products for BOD / COD reduction, odor control, and pH adjustment to allow the final stream to meet specifications for wastewater treating facilities.

Industries We Serve

For a wide range of applications worldwide, Merichem Technologies offers proven solutions for treating sulfur and other impurities across many different industries and markets including upstream, midstream and downstream oil and gas, gas treating, landfill gas, odor control, CO2 recovery, geothermal, and other renewables.

Downstream

Sulfur treatment is critical to oil and gas refining, chemical and petrochemical operations. Merichem Technologies delivers complete treatment units designed and built to your specifications. We can fast track a project using Merichem Technologies’ specifications when this better fits a client’s needs. Our technologies optimize hydrocarbon quality, protect catalysts, and ensure compliance. We also provide proven solutions for the treatment of spent caustics, reducing waste-handling costs and help minimize environmental risk due to SO2 emissions.

Midstream

Pipeline, gas plant, and storage operators rely on dependable sulfur removal with minimal downtime. Merichem Technologies delivers direct treatment achieving 99.9% H2S removal efficiency, with our LO-CAT® technology is built to run for decades with low operating costs and minimal manpower. Our advanced SULFURTRAP® adsorbents provide up to 100% H2S removal and offer long runtimes and low-pressure drop across diverse midstream applications. Merichem Technologies also offers liquid treating solutions to remove or sweeten sulfur compounds to meet pipeline and fractionator specifications for our midstream clients. Our ability to fast-track our projects using Merichem Technologies’ standards also fits the needs of our midstream client’s schedule requirements and ensures our clients can be up and running quickly.

Upstream

Upstream customers demand fast, flexible and cost-effective treatment options. Merichem Technologies provides solutions for H2S removal in light crdue, condensates, and gases, including light crude or condensate sweetening without disulfide (DSO) decomposition. Our LO-CAT technology for gas treatment offers simple, low operating costs with minimal onsite attention, while our SULFURTRAP adsorbents extend run times with low pressure drop and no bridging. Our technologies also address naphthenic acid removal ensuring safer operations and higher value production streams.

Specialty Applications

No matter where H2S is present, landfills, geothermal wells, or other industrial gas streams, Merichem Technologies delivers adaptable treatment systems to remove H2S with superior efficiency and long runtimes. Our SULFURTRAP® adsorbents last longer with lower pressure drop and our LO-CAT® technology is built to operate reliably for decades at low operating costs, making these solutions ideal for any gas treatment application.

Biofuels & Renewables

Renewable fuel producers face strict sulfur specifications that impact compliance and profitability. Merichem Technologies provides sulfur removal solutions tailored to renewable diesel, syngas, biogas and RNG reducing your operating costs and streamlining your path to economic viability. With SULFURTRAP® adsorbents and LO-CAT® technology proven in renewable diesel and biogas upgrading, we simplify compliance while improving process economics.

Merichem Technologies provides solutions that desulfurize biofuels and renewables. Designed to significantly reduce CAPEX and OPEX, our proven technologies remove sulfur and other acidic impurities from process streams, ensuring product streams meet specifications.

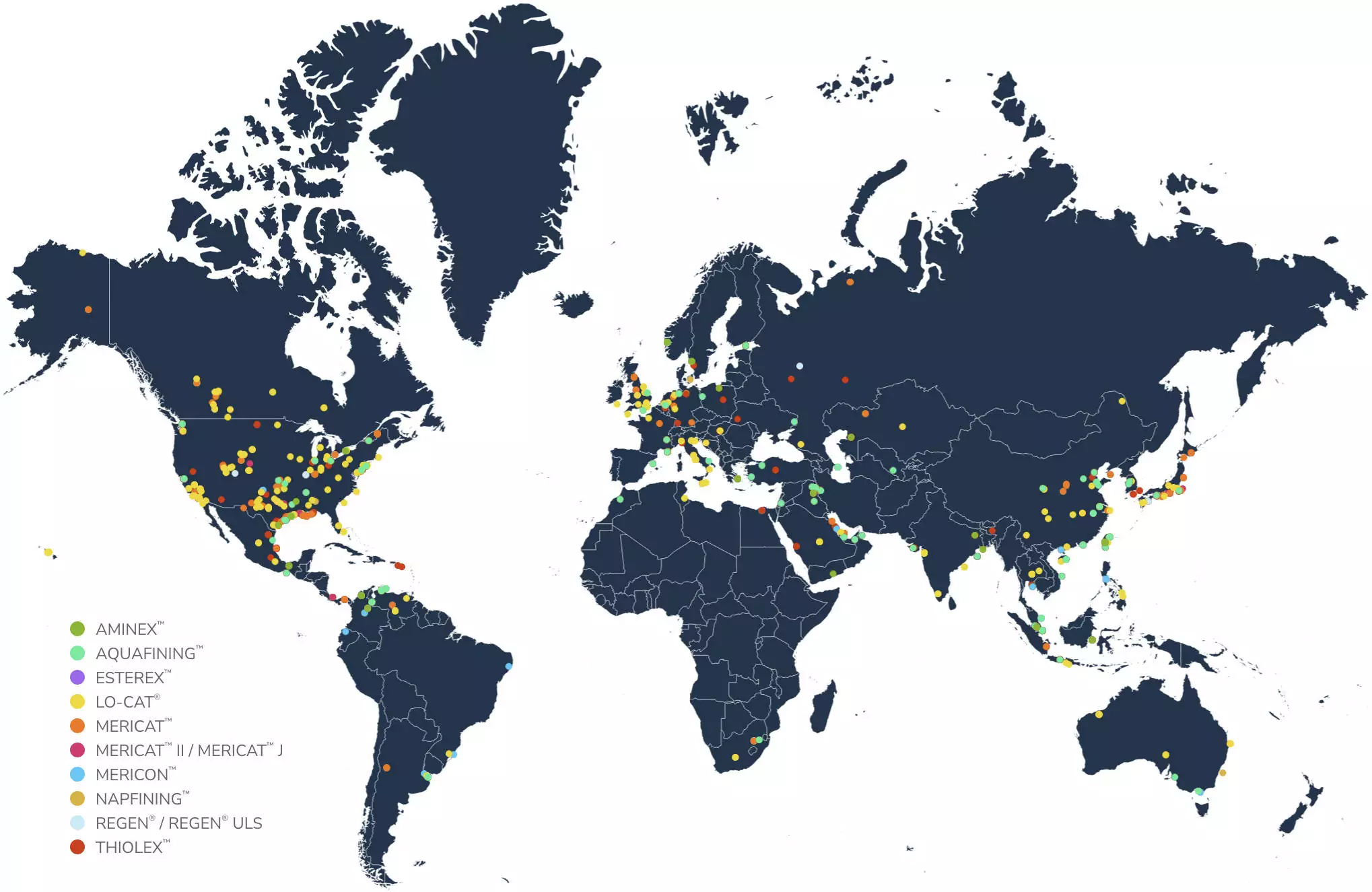

Delivering Proven Solutions Worldwide

Our solutions span the globe. With a multinational presence, we are responsive and accessible.