Proven H2S, Mercaptan and COS Treatment for Hydrocarbon Streams

Efficient, easy to operate technologies engineered for reliable operation across variable feed rates and compositions

|

Our FIBER FILM® Contactor technologies provide robust treatment for LPG, NGL, condensates, refinery gases and other hydrocarbon streams:

- High turndown to 15% for light hydrocarbon streams

- Compact vessels for easy retrofitting in existing systems

- Simple operation and low maintenance minimizing manpower requirements

- Minimum consumption of treatment chemicals and utilities reducing OPEX

- Proven technology and expert technical support built on 50 years of sulfur treatment experience

- Optimal phase separation up to 6 times faster than conventional mass transfer with minimal aqueous carryover

|

|

|

|

Cost-effective

|

Proven solutions based on

|

Trusted all over

|

We’re here to solve the Mercaptans, H2S & COS in your streams.

Help us understand your challenges by providing some details.

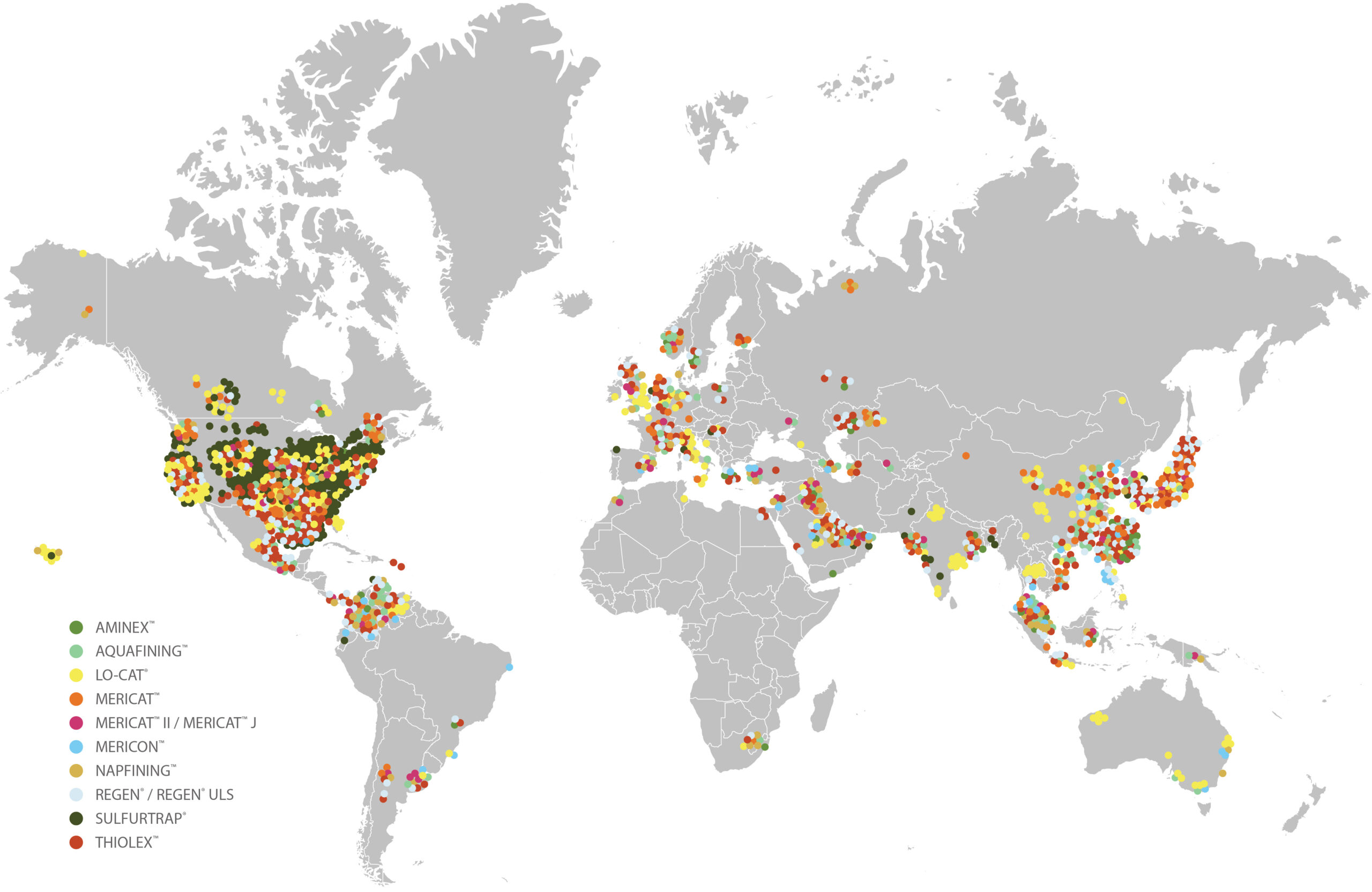

We’ve treated Mercaptans, H2S and COS all over the world.

For over 50 years we’ve helped clients like you, reliably and economically treat Mercaptans, H2S, COS and other sulfur contaminants.

With a worldwide presence, our experience includes a wide variety of industry sectors, feedstocks, treating requirements, and regulations.

Liquid Treating Solutions for Mercaptans, H2S, COS and Other Acids

Caustic Treating

THIOLEX™

THIOLEX™ is a proven technology effectively removing mercaptan compounds (RSH), hydrogen sulfide (H2S), carbon dioxide (CO2), carbonyl sulfide (COS), and elemental sulfur.

- No prewash step is required (unless caustic make-up is prohibitive)

- Low caustic make-up when combined with our REGEN® spent caustic regeneration system

- Total sulfur reduction; Achieves low total sulfur specification

- Extraction efficiency is best between 60°F to 115° F

- Gives more design and operational flexibility to remove H2S and RSH in NGL C3+ streams, increasing sales and profitability

- High-efficiency mass transfer with minimal aqueous carryover

- Additional separation vessels not required

Amine Treating

AMINEX™

AMINEX™ is a proven technology for the removal of acid gas (H2S + CO2) and carbonyl sulfide (COS) from LPG-type liquid and gas streams.

- Mitigates corrosion and plugging with no tray or packing internals

- Eliminates amine carryover

- Operates efficiently over wide range of throughputs and operating conditions

- Easily retrofit existing vessels

- No foaming

Water Wash

AQUAFINING™

AQUAFINING™ is a proven technology in the removal of dissolved and free-phase carryover of caustics, amines, surfactants and oxygenates

- Water-makeup is reduced to a minimum consumption, while reducing CAPEX and space requirements

- Process produces spent alkaline water that can be easily handled in wastewater treatment plants

Naphthenic Acid Extraction

NAPFINING™

NAPFINING™ is a proven solution for removing naphthenic acid compounds from jet fuel, kerosene, diesel, condensate and crude oil streams—without causing debilitating emulsions.

- Reduce space cost requirements for operators

- Minimal emulsion formation

- Better performance than electrostatic precipitation for emulsion prevention

- Ideal solution for removal of TAN from hydrocarbons in the range of 0.1 to 1 mg KOH/g or above; has commercially treated up to 0.5 TAN in the feed