Proven H2S Removal Solutions Built for Demanding Gas Processing

Adsorbent and Liquid Redox Technologies with Flexible Deployment Options

With decades of expertise, Merichem Technologies is uniquely positioned to solve your challenges, efficiently, and economically with proven low maintenance solutions for reliable H2S control, even under variable conditions.

Lease and Purchase Options | Lifecycle Support

|

|

|

|

Cost-effective

|

Proven solutions based on

|

Trusted all over

|

We’re here to solve your H2S issues.

Help us understand your H2S treatment challenge by providing some details.

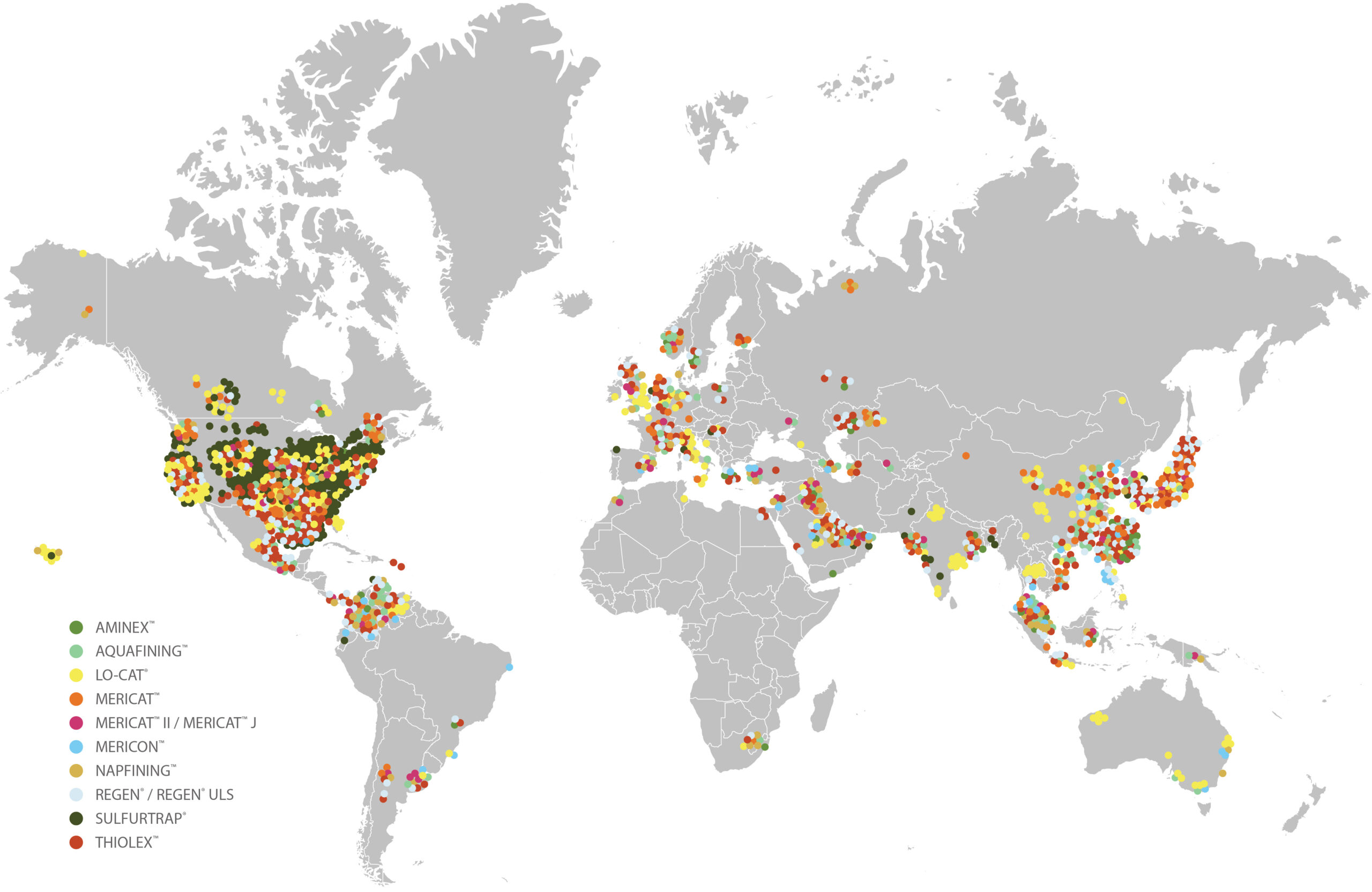

We’ve treated H2S all over the world.

For over 50 years we’ve helped clients like you, reliably and economically treat H2S and other sulfur contaminants.

Our experience includes a wide variety of industry sectors, feedstocks, treating requirements, and regulations.

Engineered for reliable H2S removal across variable gas compositions.

Our SULFURTRAP® adsorbents and vessel systems and LO-CAT® liquid redox technologies support natural gas processing and LNG operations at any scale. From rapidly deployed adsorbent vessel systems to high-capacity liquid redox units, each solution is designed to align with your gas stream and operating objectives.

With over 50 years of experience delivering sulfur treatment technologies, adsorbents, catalysts and technical support, our team provides reliable solutions, simple operation and long-term partnership.

SULFURTRAP Non-Bridging Media & Continuous Operation Vessels

OPEX as low as 2¢ per MCF

- Handles flow rate & H2S concentration variability

- No hydroblasting for faster & safer change-outs

- High-capacity SULFURTRAP® adsorbents

- 0 ppm H2S outlet

- Handles high CO2 & light mercaptans

- Optional changeout & installation services available

OPEX cases are based on treating gas at 50 ppm H2S

LO-CAT®: Proven, Flexible & Operator-Friendly

OPEX as low as 0.2¢ per MCF

- Process guarantees <1 ppm H2S

- High turndown (up to 100%)

- Continuously regenerated catalyst

- No liquid waste streams

- No hazardous waste products produced

OPEX cases are based on treating gas at 50 ppm H2S

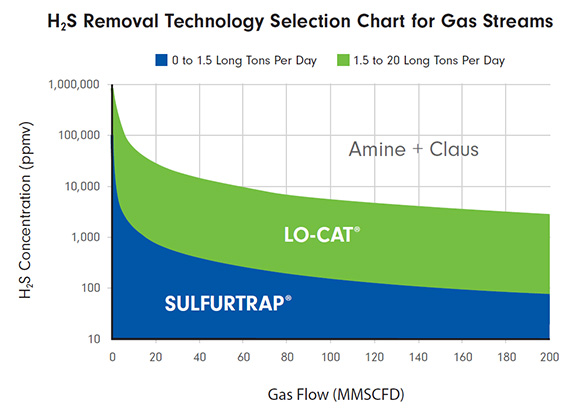

Selecting the right H₂S removal solution for your operations

Merichem Technologies has a solution for the H2S present in your streams. The chart offers suggested ranges for our SULFURTRAP® media and LO-CAT® liquid redox technology.

If your flow or H2S concentration is between the two areas, we are happy to help you confirm which system could be most appropriate based on the needs of your operations.