H2S Removal Vessel Systems

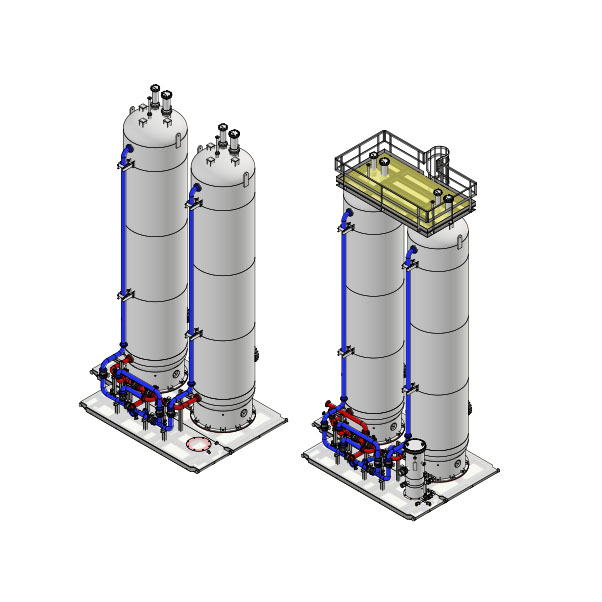

Packaged Lead-Lag Vessel System with SULFURTRAP® Adsorbent Media

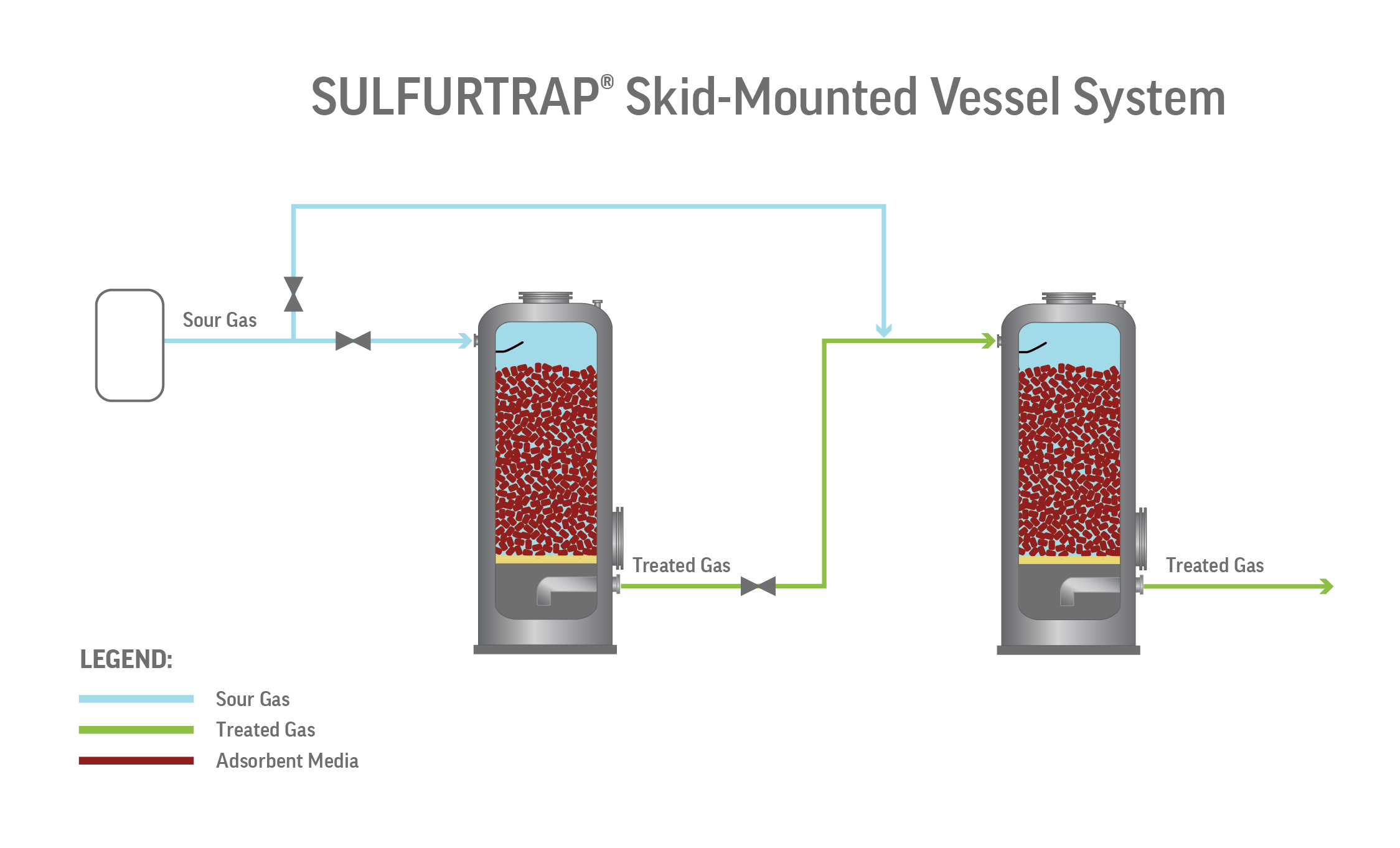

Our Skid-Mounted Lead-Lag Vessel Systems using SULFURTRAP® adsorbents provide reliable H2S and light mercaptan removal for oil and gas, biogas, landfill gas and other industrial streams.

Designed for continuous operation, these packaged systems are in a vertical lead-lag configuration including SULFURTRAP® adsorbent media for maximizes sulfur loading, extends run life, and allows uninterrupted operation during media changeout.

Standard sizes are available for immediate lease or purchase, with custom engineered systems also available.

Why SULFURTRAP® Adsorbents?

SULFURTRAP® adsorbent media is engineered for high-performance H2S removal in variable conditions commonly found in oil & gas, biogas and landfill applications.

Key Performance Advantages:

- High sulfur loading for extended run life

- Low, stable pressure drop through end-of-run

- Complete H2S removal

- Handles fluctuating concentrations and flow rates

- Performs reliably in CO2-rich streams

- Easy and safe media change-outs

- No O2 or high relative humidity needed

SULFURTRAP® Lead-Lag Skid-Mounted Vessel System Advantages

- Continuous, uninterrupted operation

- Available for lease or sale

- Short lead times; certain sizes available immediately

- Compact, vertical skid design minimizes footprint

- Built to US Gulf Standards

- Meets NACE MR0175 requirements

- Designed to easily add optional upstream liquid/gas separator and downstream fines filter

- Optional adsorbent fill and change-out services available

These vessels are designed to maximize H2S removal with SULFURTRAP® adsorbents

Adsorbent solutions for gas and liquid streams: View SULFURTRAP® Line »

Lease or Purchase Options to Match Your Project

Our skid-mounted H2S removal vessel systems with SULFURTRAP® adsorbent media are available for lease or purchase, allowing you to align with your project timelines and budget.

Ideal for Leasing When:

- Temporary or pilot projects

- Early production facilities

- Permit-driven timelines

- Emergency H2S mitigation

- Bridge solutions while permanent facilities are built

Established Performance

For over half a century, Merichem Technologies has provided innovative technology and equipment to the oil and gas industry. With proven solutions, we’ve helped our customers eliminate the obstacles to performance and profitability.

Comprehensive and Committed

In addition to a range of proprietary treatment technologies, Merichem Technologies offers engineering, design, fabrication, analytics, testing and service support to help our customers meet their specifications, performance and warranty requirements.